Source of picture : website of research project for developing books and home pages,

Srinakarinwirot University, subject Food processing industry for middle and small company

UBIS (Asia) Public Company Limited is a manufacturer and distributor of high quality specialty chemicals and to be used as a component in the manufacture of metal packaging such as metal cans, food packaging, food container, metal containers contain both 0.5 liters and 200 liters of chemicals, such as spray cans. It also includes an aluminum tube filled with pharmaceuticals or cosmetics. All products of the company have been produced and developed underneath of the formula and technology of the Company. In the business of the Company will focus on contact with each customers in close coordination to learn about the needs or problems of using the products with our Technical Sales Team, a team of experienced in technology and development professionals who develop the qualities of the products. The Company ensure to provide and all responses as customer needs even the service or quality of the products for properly work with customers' production process.

The Company was granted with the promotional privileges by the Board of Investment for Sealing Compounds products with the privilege of exemption from corporate income tax for a period of 8 years, the tax privilege has started since October 1 , 2014 toward.

UBIS (Asia) Public Company Limited is certified by ISO 9001:2015, the Quality Management System, we ensure to provide high quality of products and keep continuous improvement in accordance with ISO 9001:2015, we are elevating to compliance with Environmental concern toward ISO14001, Environmental Management System. The company has restructured department of Research and Development (R&D) directly report to Managing Director (MD) for agility and operation of the company’s strategy. Besides, we have an experienced specialist team to strengthen our product development unit to be equivalent with the international competitors and target to create new products as well as mordenize the production process.

Maintaining good relationship and cooperation along with customers as business partnership. Beyond fast responsiveness, on-time delivery and after sales service, there would be coordinately participate between UBIS and customers to jointly research and develop project to meet their utmost satisfaction.

UBIS products are food grade chemicals as upstream supply chain of Metal Packaging Industry. Therefore, customer satisfaction for entire industrial chain will be UBIS’s aim with highly concern in quality products, continuous improvement and after sales service for long term business relationship.

Brand perception in global market is one of overseas strategy with international networking agents or distributors who are knowledgable and understanding in the industry to promote UBIS products, create more distribution channel and local services directly to each local potential customers.

Besides, UBIS must comply to international standard, regulations and other requirements of global food organization such as US-FDA, EU Directives, HALAL and etc. UBIS main products will be allocated by 2 categories :

1. Sealing CompoundsLatex can be used as a sealant for metal packaging. Its key function is to prevent leakage between the can and the lid, both the bottom lid and the top lid during container production process. After the food or container has been placed in the container, the container must be kept in good card to prevent any external contamination from entering into the container, thereby extending the shelf life of the product packed in the container. It also has to withstand the internal sterilization process of the production process.

1.1 Water base sealing compoundUBIS has been supplying water base sealing compound into two types of packing products

PVC based compound for sealing purpose such as closure and lid cover

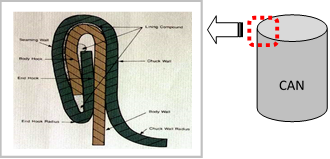

Below is a picture of seaming process of can end production (Double seam) (Body hook) (End hook) and (Lining compound)

Source of picture : website of research project for developing books and home pages,

Srinakarinwirot University, subject Food processing industry for middle and small company

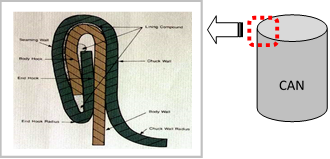

Below is a step of lining compound from bare end, lining compound process and lined compound. To prevent any leakage of the packaged product, and to prevent the entry of air into the can.

Source of picture : www.cancentral.com และ Visypak Beverage Packaging “Beverage Manufacturing Processes”

Canned coatings Solvent Base Lacquers, which is used to protect the substrate surface by coating both inside and outside. The internal lacquer must have the ability to withstand pH of the packed goods especially food items with different pH. This prevents the packed food from to react to the substrate and make changes in the color, flavor and taste of the food in the can in order to keep its shelf-life. The external coating lacquer will protect the external surface of the tin from corrosion, scratching, corrosion, and as a primer for exterior canning with outside printing and varnish for more beautiful packaging thus it has to be good flexibility. The Company has the marketing policy to cover all parts of the market, the main customers are Food and Beverage Products and Industrial Products. The company began to introduce new products for a variety of products to customers as an alternative and to accommodate the new needs of customers in each segment, and develop the distribution system to cover all parts of the domestic market (Full Segmentation Coverage)

2.1 Packaging for Food and Beverage products. Food and beverage cans are a core product line in metal packaging industry 2.1.1) Packaging for food can such as tuna can, sardine can, fruit and vegetable can.

Beyond sealing compound and coating lacquer as UBIS core business, we were appointed as authorized distributor in Thailand of 3 product categories from well know manufacturers in metal packaging industry 1) Quaker Chemical from United States of America, Can making lubricants is high performance product metal packaging 2-Piece beverage can. 2) M-Dec Enterprise Pte Ltd. from Singapore, Lithographic printing inks for metal decoration. 3) Salchi Metalcoat Srl. from Italy, Side seam powder protection for 3-Piece can.

For the customer care policy by focusing on the domestic target customers, the Company began to introduce new products for a variety of products to customers as an alternative. In addition, we are able to meet the new demands of our customers in each segment or full segmentation coverage. For the foreign markets, the Company have a customer base spread across in many continents by dividing in 2 groups are;

Target group in China market, the Company conducts 2 transactions;

Target customers in other international markets;

The company has established a network partner by appointing a distributor or consultant, it can serve customers in each country effectively underneath of the Company's technical support to agents and customers in each country. The target group is a manufacturer of canned food, beverage and other industrial containers therefore, the Company must analyze factors of sales affecting, such as the quantity of competitors, monopolies, market size, and market growth in each customer segment prior selecting the target market.

International Marketing focus on promoting product by offering a trial product including the regularly visiting plan throughout the year to exchange any ideas, any advice and any issues of each business area to improve production and product development. The Company has a policy to participate in exhibitions worldwide and in the region continuously in order to build our brand recognition to customers. The company joined the following shows :

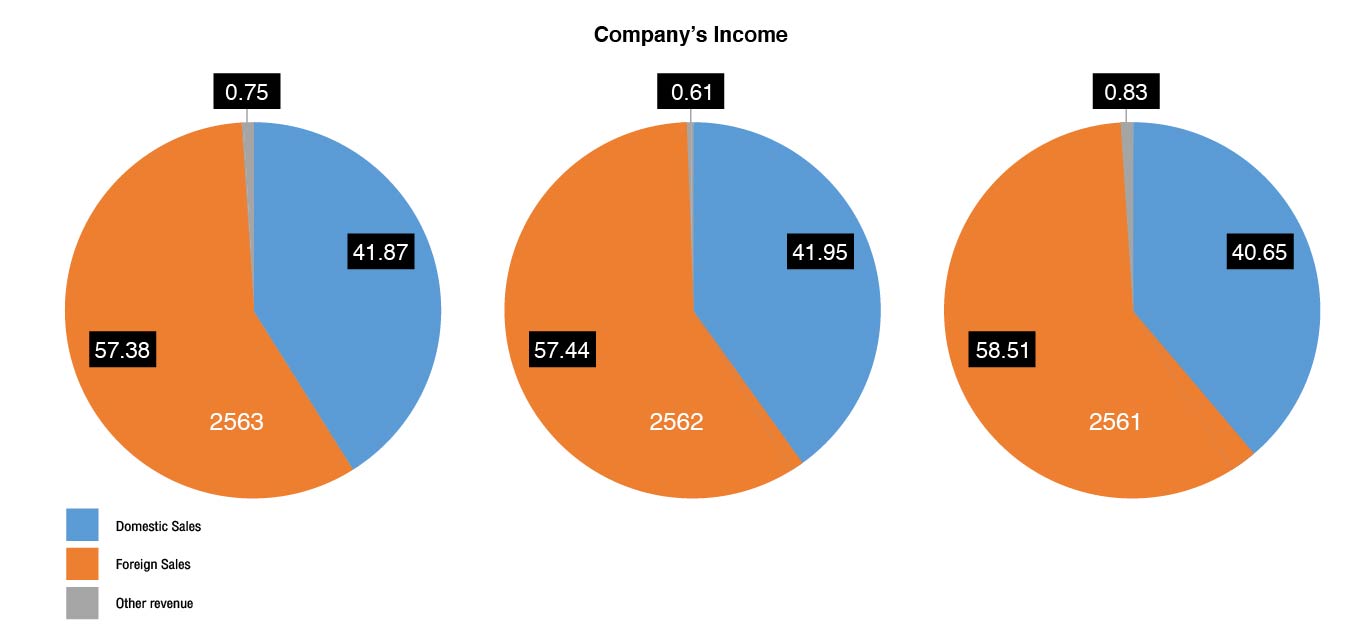

The company's sales in 2020 were at 1,031 Million Baht, increase of 12% when compared with 2019.The domestic market and the foreign market increased to a similar, as the result, the ratio of total sales domestic sales : foreign sales are 41.87% : 57.38%, and other revenues of 0.75% which meet company’s target for both domestic and oversea market expansion. The Company's revenue structure are as follows:

Revenue Structure

| Unit : Thousand Baht | ||||||

|---|---|---|---|---|---|---|

| 2020 | 2019 | 2018 | ||||

| Revenue | % | Revenue | % | Revenue | % | |

| Sales Revenue | ||||||

| - Domestic (1) | 431,494 | 41.87 | 384,417 | 41.95 | 380,983 | 40.65 |

| - International | 591,370 | 57.38 | 526,290 | 57.44 | 548,371 | 58.51 |

| Total Revenue from Sale | 1,022,864 | 99.25 | 910,707 | 99.39 | 929,354 | 99.17 |

| Other Revenue (2) | 7,779 | 0.75 | 5,569 | 0.61 | 7,819 | 0.83 |

| Total Revenue | 1,030,643 | 100.00 | 916,276 | 100.00 | 937,173 | 100.00 |

Note:

(1) The domestic revenue includes the sales revenue from products distributed by the Company (Including Quaker, Printing Inks products and Power side stripe)

(2) Other revenue consists of commission, other services, selling of scrap materials, interests earned, profits from currency exchange (if any), and export compensations

Our product marketing aims at market share in the international market with specialized and excellent innovation. Therefore, we have been developing our can coating and compound with good quality and also in time delivery to suit customers satisfaction under “UBIS” brand to expand our products to Asian and worldwide market.

Marketing policy in 2020, Based on COVID 19 situation, we have focuses on product quality that meets the needs of potential customers which resulted in the international sales growth rate of 11 percent, while the export volume of canned seafood and canned fruits and vegetables of Thailand this year fell 0.45 percent. Because of The dollar strengthened by 0.6 percent and the yuan strengthened by 1.4 percent, both of which were the main export currencies of the company. As a result, the ratio of overseas sales increased 12.27 percent, which makes this year the company has a proportion of foreign sales to domestic sales is 42:58 which is a challenge for the company to compete with other manufacturers that are multinational companies and are sold worldwide. For the domestic market, we have focused on cooperation with customers to improve the quality and variety of products throughout the service in order to maintain our market share and growth. In 2020 the domestic market growth rate 12.25 percent.

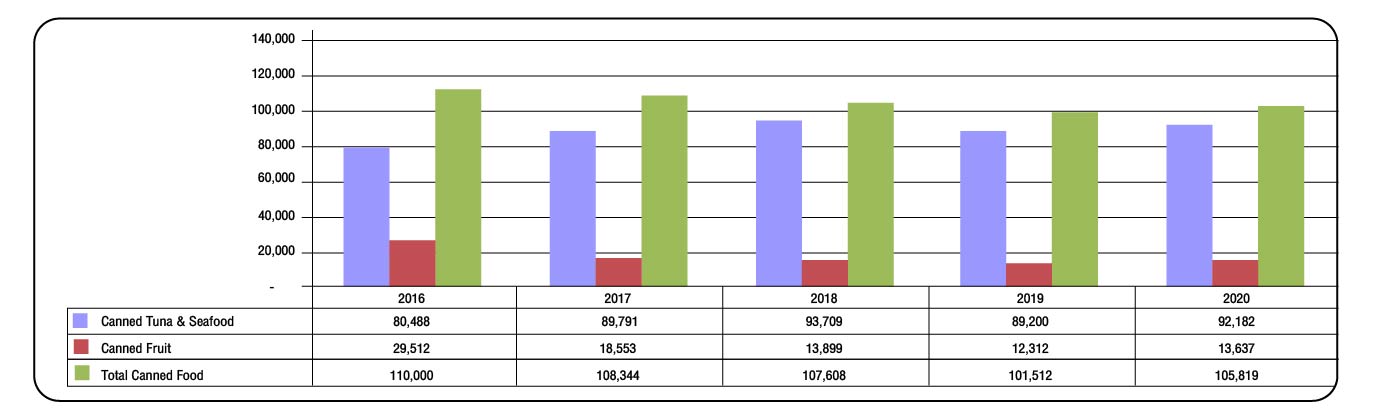

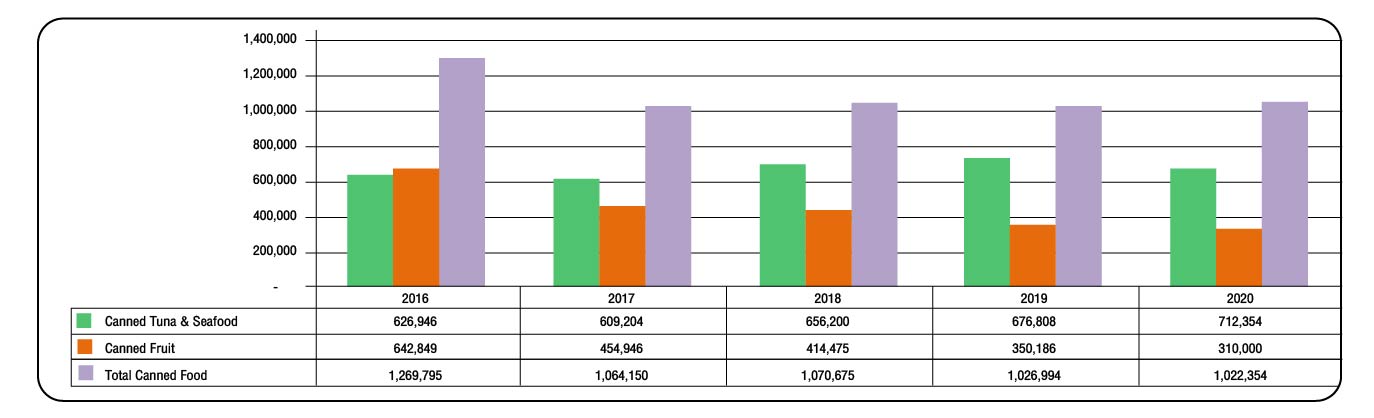

The situation of the canned food industry according to the information of Thailand’s canned food export value from Ministry of Commerce in 2020 was 105,819 Million Baht, increase from the previous year by 4.23 percent. The export volume was 1,022,354 Tons, decreased 0.45 percent from the previous year.

Value of Thailand’s Canned Food Export (Million Baht)

Volume of Thailand’s Canned Food Export (Metric Ton)

** Source: Information and Communication Technology Center of the Office of the Permanent Secretary, Ministry of Commerce by the cooperation of the Customs Department

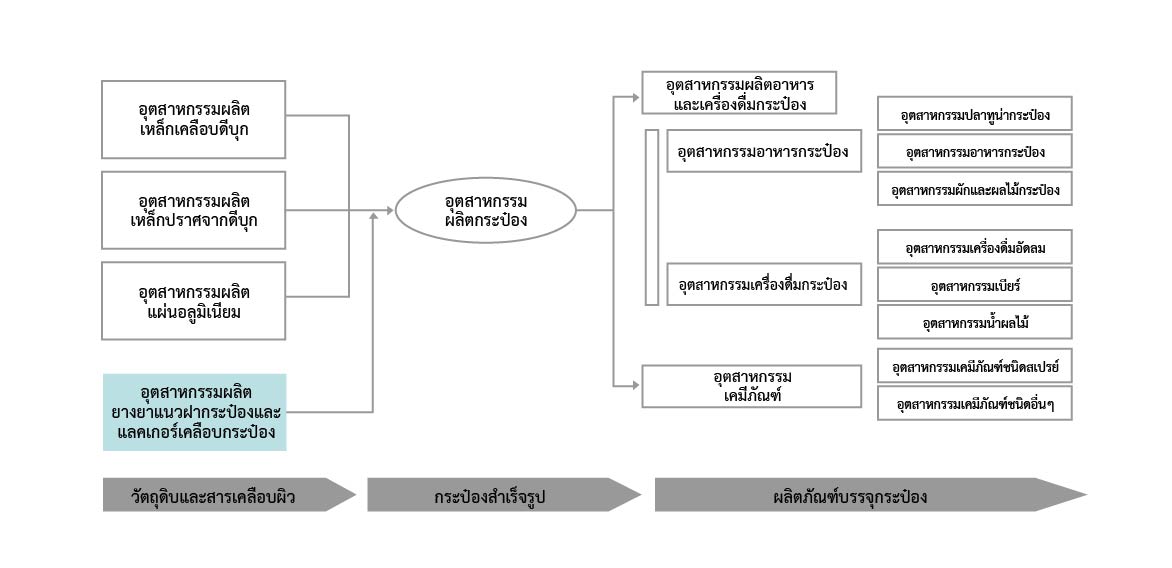

In terms of Industrial competitiveness of Thailand's canned production industrial, cans can be used in the food and beverage industry and chemical industry which the highest canned industry was canned food and beverage industry.

The connection of Sealing Compound and Lacquer industries with other industries

Sealing Compounds, in this market segment there are only UBIS and other one competitor. The competition depends on the acceptance of the technology and the reliability of the manufacturers. Therefore, considering the competition, situation of sealing compound, it is rather few. The proportion of sales is similar, meanwhile in the foreign markets, competitors are large multinationals, thus, opportunity can be seen. Therefore, the Company focuses on research and development of quality products and production standard to meet the needs of users and to be equally acceptable in the industry

Lacquers, in this market of can coating industry. The Company is the only Thai manufacturer with market share in the top five in the domestic market which is similar to multi national competitors. The market share is similar, therefore, competition in lacquer market is moderate and each competitor in the market has its own unique expertise and having their own customer base including the characteristics of the business and technology of the industry that is why there are no new manufacturers into this business

The company’s factory is located at Samut Sakorn Industrial Estate (SIE) in Samut Sakorn Province with semi-automation by industrial digital computer PLC process control system our high technology of production process will leads to high productivity, stability of quality control and on-time delivery. Both Sealing Compound and Coating Lacquer plants are certified with ISO 9001 Quality Management System Standard as well operational system for ISO14001 Environmental management and ISO45001 Occupational Health and Safety in near future.

The company is also certified by The Central Islamic Council of Thailand (CICOT) under “HALAL” that gurantees our Sealing compound and Lacquer products meet the requirement of Islamic law. Therefore our products can be distributed to Muslim contries without concerns

Production Capacity

| Production Capacity | 2020 | 2019 | 2018 |

|---|---|---|---|

| (Unit : Metric Ton) | |||

| Water Based Sealing Compound | 9,000*** | 9,000*** | 9,000*** |

| Coating Lacquer | 11,400 | 6,000 | 6,000 |

| Total Capacity | 20,400 | 15,000 | 15,000 |

| Maximum Production Capacity Rate | 25,000 | 19,000 | 19,000 |

Remark : *** included the production in China

The Company have a production policy that is focused on quality products to meet the needs of customers and can deliver products on time. It also develops new products to support new technologies and requirements. This is to focus on building confidence in our customers and continuously promoting our products.

Sourcing Material : Main raw material of sealing compounds and lacquers are petrochemical products such as resin, solvent, polymer and other chemicals are imported directly from manufacturers or local distributors, agent in Thailand. Due to fluctuation of world supply and demand, foreign exchange currency, we have to effectively manage our inventory system, lead time and price of material which will effect to cost of production.

Thailand is world’s leading producer of natural latex which is core raw material of Sealing compound which is highly fluctuated by demand and supply in world market. Currently, UBIS has sourcing ratio 70:30 of domestic raw material and import from overseas.

In compliance with ISO 9001 : 2015 UBIS must qualify the supplier lists with qualifications 1) On time delivery 2) Reliability 3) After sales service. Moreover, compliance on quality of material and competitive cost will be considered too.

Green Industry : UBIS highly cares on environmental impact of waste from production process, therefore, we has developed an environmentally friendly production process in accordance with ISO 14001-2015 and the company has received “Green Industry Level 3 ” certification from the Ministry of Industry and the Department of Factory. We have focuses on storing raw materials by separate the raw materials and finished goods. In addition, we uses the occupational health and safety management system ISO 45001-2018. We heve safety committee which are responsible for determining safety measures in the workplace and alarm system. To make employees know the standard of safety in work and knowledge about working with flammable materials as well as a workshop on fire management and safety.

The Company has prepared an annual plan to regularly analyze the environment in production area in order to monitor and find preventive measures immediately. In the past year, there were no environmental problems or failed criteria. According to the law, the Company has focused on establishing the work procedure, especially safety in work. Furthermore, the employees strictly follow the instructions of using of safety devices in work as the policy of accident prevention and health, and always coordinate with the Industrial Estate for trainings.

The Company has built the fire prevention system with fire tighting plan, and annual rehearsal fire evacuation to employees to ensure we will be able to effectively handle and manage the emergency incident with minimal impact to the environment and nearby community.

In 2020, there was no dispute cases of environmental problems